Another accidental adventure in radical brewing:

I was called away just as the kettle was on the verge of boiling. I turned the flame down to the lowest level that a small gust of wind could not extinguish, put the lid on the kettle, and asked my lovely wife to keep an eye on the flame for me while I was gone.

Thusly I figured to kill two birds with one stone by preventing infection and drastically reducing the time needed to re-catch the boil upon my return. Normally I lose the boil when I set the flame this low so I anticipated that the flame would hold the wort in the neighborhood of 165° or above. Perfect to keep the wort from souring and allow an easy re-acquisition of boil temps later . . . right?

Four hours later . . . returned to find that the whole volume of wort had been holding at a low boil for the duration of my absence. I proceeded to remove the lid, add the bittering hops, infuse 1.7 L of boiling water to replace the boil-off, and continue with the planned boil schedule.

I expect the final product will be darker in color, possibly have more body, a more pronounced caramel flavor, and perhaps slightly higher FG due to the unfermentable sugars created by carmelization. I'm keeping my fingers crossed that one hour of open boiling was long enough to boil off all the DMS created during the previous four hours of lid-on boiling. I'll let you know . . .

Technical Details:

Beer Recipator Recipe

Schlemazl Brews

Tuesday, January 21, 2014

Saturday, January 5, 2013

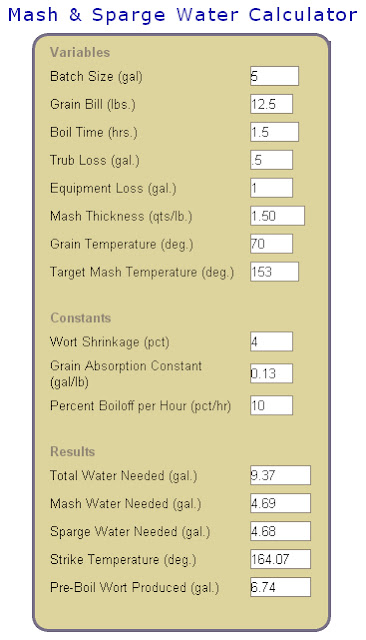

Schlaflyish ESB

So there I was. My target mash temp was 153 F. According to both Brew365 and Hopville this temperature aught to be achievable by mixing 4.5 gallons of 166F water with 13.75 lbs. of 65F grist. Using my brand new Taylor waterproof compact digital thermometer, I determined that the strike water was less than one degree fahrenheit over 166. Dough-in time!

Then, out of the blue, for the first time since I've been all-grain brewing, tragedy struck. Once I mixed the grist with the strike water thoroughly, I proceeded to take a temperature reading with my handy new thermometer. Result? The mash temperature was only 149F!

One-hundred and forty-nine Fahrenheiting degrees!!!

This would be perfect if I were brewing a Belgian blonde or the like--all starches become easily fermentible sugars, making for a thin, dry, highly attenuated brew, almost no unfermentable dextrins. However, as the reader may have guessed, I was NOT making a Belgian blonde. No ma'am. Today was Schlafly Winter ESB clone day. ESB (or English Extra-Special Bitter) as a style is neither thin, nor dry. It is full-bodied, malty (balanced with a good dose of hop bitterness and flavor), and almost sweet. Anything but thin and dry.

Time to improvise a plan B. And quickly! Our mash temperature has come in almost 5 degrees below target, and we have less than 5-minutes to take bold corrective measures, or write yet another batch off as a potentially delicious brew lost to poor temperature control.

What to do? What to do? . . . Fortunately, I just happened to have a little less than 2 gallons of water already boiling in the kitchen in preparation for mash-out. Adding this directly to the mash within 3 minutes of dough-in raised the temp to 154F. (I don't have a good reason for why I already had the mash-out infusion at full boil a full hour before it was supposed to be added. So don't ask.)

But was the beer saved? We'll just have to wait and see.

S.G. 1.047

O.G. 1.059

Here is the Beer Recipator version.

January 5, 2013 Tasting

S.G. 1.017--This is a good number. Apparently the cooler-than-optimal initial mash in was counteracted by my good luck and quick thinking in adding the boiling mash-out water at the beginning of the mash instead.

Good bitterness. Body is good at room temperature I hope this holds up when chilled. Very little aroma. A bit fruity in a way that is comparable to other ESB's I've tasted. Not mind blowing. Not bad either.

I'm detecting an off flavor. Having trouble identifying it. This batch (along with all the others I brewed in December 2012) fermented cool--between 60F & 65F. I'm going to bring it upstairs to rest at warmer temps for a couple of days before kegging. Then I'll bring in my team of beer tasters to help me identify the remaining problem, if any.

Monday, November 19, 2012

Nutz!

Grape Nuts cereal? As an adjunct? The heck you say‽‽‽

Heck yes! I do say!

Here's the recipe. Inspired by this ancient article in BYO.

Mash

4.5 gallons 163.0° F strike water dechlorinated with 1/2 campden tablet (potassium metabisulfite).

Grain bill:

8 lbs. Breiss American 2-row

3 lbs. Post Grape Nuts Cereal

8.25 oz. American Crystal Malt 60-lovibond

1 oz. British Black Patent Malt

1/2 lb. Rice Hulls (a precaution to prevent a stuck sparge)

Temperature Management

Boiled 4 1/2 gallons of water on Brew Day Eve. Transferred this at near-boiling temperature to the mash tun around midnight and let it sit overnight. 8:30 the next morning the temp in the tun was 109F. Not bad. I was hoping for better.

Dough-in occurred at 9:55 a.m. mash temperature = 150.5° F. Perfect! 1 hour later the temperature in the mash tun was 146°. Again, I was hoping for better.

Next time I'll boil 6 full gallons of water the night before and transfer all six gallons to the tun. On Brew Day, I'll take 4.5 gallons back to the HLT and leave the remainder in the tun until the strike water has been re-heated. Finally I'll drain the mash tun just before draining the full contents of the HLT to the tun one final time. Also I'll be more patient about waiting for the liquor to fall to strike temp. This time I kept recirculating 1 gallon at a time out through the spigot into a pitcher and back into the tun again until I got within a few degrees. Next time I'll stop this process when I'm within 10 degrees of my target strike temp, or even farther.

Sparge

Good thing I included those rice hulls. I've never had a stuck sparge since I started AG brewing about a year ago, probably because I batch sparge. This was the closest I've ever come to a true stuck sparge. Runoff was painfully slow. If I ever get silly and brew with Grape Nuts again, I'll definitely use rice hulls. Perhaps a whole pound of them.

Boil

Hop Additions

1.5 oz. of Tettnanger 6.1% alpha acids @ 45 min

.5 oz. of Tettnanger 6.1% alpha acids @15 min

Irish Moss @ 15 min.

O.G. = 1.050

Fermentation

Pitched directly onto the Surly Furious Clone yeast cake.

Primary fermentation was held at 60°F for the first week. On Tuesday 11/6/2012 (nothing else of import happened that day, except I hear that Halo 4 was released) there was still a good inch of kraeusen on top of the beer. Specific Gravity reading was 1.018. Almost done. Tastes like Grape Nuts, in a good way. A little sweet. Slightly salty--which adds to the interestingness of this experimental brew.

On Thursday 11/8/2012 the primary fermenter was moved to a 69°F environment in hopes that the warmer temperature will stimulate the yeast to finish their job. Hopefully the final product will have an FG of < 1.015.

Finishing, Bottling, and Drinking

Bottled on 11/18/2012. FG = 1.013-1.014; the extra week at warmer temps did the trick. Used 4 oz. of dextrose dissolved in 2 cups of pasteurized water in a pasteurized Pyrex measuring cup. Bottled directly from primary

Tasting notes:

Christine, having been given a room-temperature un-carbonated sample on bottling day, without any inkling of what she was drinking, said, "A mild sweet red ale. Sweet but not too heavy. It has a little bit of berry-ness to it without being a particular berry, maybe like a strawberry. It's like Pi Common meets an un-hopped Surly Furious Lite."

Knowing what I was drinking made it impossible for me to be as objective as possible. Knowing how much salt they put in Grape Nuts cereal makes me extra sensitive to the saltiness of the finished product. I know I should be pleased that it was able to ferment at all with so much salt in it. And I'm not displeased. It's just that the saltiness is the first and last thing I notice in every sip. The fact that Christine, tasting blindly, didn't seem to notice this flaw is heartening.

That said, the finished beer really does taste like Grape Nuts. This is obviously what I was going for, and the flavor is not out of place in a malt-forward brew such as this. There is more hoppiness here than in, say, a Scottish beer or an English brown or porter/stout, but not too much more. Much less hop flavor than in an American pale ale certainly.

Note to self: do not brew this exact recipe again. For that matter, do not use 3 whole lbs. of Grape Nuts in any future 5-gallon batches.

In the future I will not rule out Grape Nuts as an adjunct if I'm looking for the specific flavor profile it imparts. I will limit the amount I use to 1-1.5 pounds/5 gallons of finished beer. This should make the distracting saltiness practically disappear. Whether or not the delicious grapey-nutty flavor from so many weekday breakfasts of my childhood will still show up at that lower concentration will have to wait to be seen.

Heck yes! I do say!

Here's the recipe. Inspired by this ancient article in BYO.

Mash

4.5 gallons 163.0° F strike water dechlorinated with 1/2 campden tablet (potassium metabisulfite).

Grain bill:

8 lbs. Breiss American 2-row

3 lbs. Post Grape Nuts Cereal

8.25 oz. American Crystal Malt 60-lovibond

1 oz. British Black Patent Malt

1/2 lb. Rice Hulls (a precaution to prevent a stuck sparge)

Temperature Management

Boiled 4 1/2 gallons of water on Brew Day Eve. Transferred this at near-boiling temperature to the mash tun around midnight and let it sit overnight. 8:30 the next morning the temp in the tun was 109F. Not bad. I was hoping for better.

Dough-in occurred at 9:55 a.m. mash temperature = 150.5° F. Perfect! 1 hour later the temperature in the mash tun was 146°. Again, I was hoping for better.

Next time I'll boil 6 full gallons of water the night before and transfer all six gallons to the tun. On Brew Day, I'll take 4.5 gallons back to the HLT and leave the remainder in the tun until the strike water has been re-heated. Finally I'll drain the mash tun just before draining the full contents of the HLT to the tun one final time. Also I'll be more patient about waiting for the liquor to fall to strike temp. This time I kept recirculating 1 gallon at a time out through the spigot into a pitcher and back into the tun again until I got within a few degrees. Next time I'll stop this process when I'm within 10 degrees of my target strike temp, or even farther.

Sparge

Good thing I included those rice hulls. I've never had a stuck sparge since I started AG brewing about a year ago, probably because I batch sparge. This was the closest I've ever come to a true stuck sparge. Runoff was painfully slow. If I ever get silly and brew with Grape Nuts again, I'll definitely use rice hulls. Perhaps a whole pound of them.

Boil

Hop Additions

1.5 oz. of Tettnanger 6.1% alpha acids @ 45 min

.5 oz. of Tettnanger 6.1% alpha acids @15 min

Irish Moss @ 15 min.

O.G. = 1.050

Fermentation

Pitched directly onto the Surly Furious Clone yeast cake.

Primary fermentation was held at 60°F for the first week. On Tuesday 11/6/2012 (nothing else of import happened that day, except I hear that Halo 4 was released) there was still a good inch of kraeusen on top of the beer. Specific Gravity reading was 1.018. Almost done. Tastes like Grape Nuts, in a good way. A little sweet. Slightly salty--which adds to the interestingness of this experimental brew.

On Thursday 11/8/2012 the primary fermenter was moved to a 69°F environment in hopes that the warmer temperature will stimulate the yeast to finish their job. Hopefully the final product will have an FG of < 1.015.

Finishing, Bottling, and Drinking

Bottled on 11/18/2012. FG = 1.013-1.014; the extra week at warmer temps did the trick. Used 4 oz. of dextrose dissolved in 2 cups of pasteurized water in a pasteurized Pyrex measuring cup. Bottled directly from primary

Tasting notes:

Christine, having been given a room-temperature un-carbonated sample on bottling day, without any inkling of what she was drinking, said, "A mild sweet red ale. Sweet but not too heavy. It has a little bit of berry-ness to it without being a particular berry, maybe like a strawberry. It's like Pi Common meets an un-hopped Surly Furious Lite."

Knowing what I was drinking made it impossible for me to be as objective as possible. Knowing how much salt they put in Grape Nuts cereal makes me extra sensitive to the saltiness of the finished product. I know I should be pleased that it was able to ferment at all with so much salt in it. And I'm not displeased. It's just that the saltiness is the first and last thing I notice in every sip. The fact that Christine, tasting blindly, didn't seem to notice this flaw is heartening.

That said, the finished beer really does taste like Grape Nuts. This is obviously what I was going for, and the flavor is not out of place in a malt-forward brew such as this. There is more hoppiness here than in, say, a Scottish beer or an English brown or porter/stout, but not too much more. Much less hop flavor than in an American pale ale certainly.

Note to self: do not brew this exact recipe again. For that matter, do not use 3 whole lbs. of Grape Nuts in any future 5-gallon batches.

In the future I will not rule out Grape Nuts as an adjunct if I'm looking for the specific flavor profile it imparts. I will limit the amount I use to 1-1.5 pounds/5 gallons of finished beer. This should make the distracting saltiness practically disappear. Whether or not the delicious grapey-nutty flavor from so many weekday breakfasts of my childhood will still show up at that lower concentration will have to wait to be seen.

Surly Furious Clone by Northern Brewer

Brew date: 10/19/2012

Starter:

Boiled 1.8L (final volume) of 1.043 SG starter wort for 15 minutes on Thursday night 10/18/2012. (Wort came from final runnings of Lakefront Fixed Gear Clone. Pitched 1 Activator smack pack of WYeast British Ale II into this starter wort first thing in the morning on Friday Oct. 19.

Mash-in:

Used 3 gallons of boiling water to pre-heat the mash tun. 4.5 gallons 165.5F strike water & 13.38 lbs of cool grain--it's 53F in Kirkwood today and the grain had been outside for a while--combined to reach 153.1F after mash in @ 2:45 p.m. Since my target temp was 153, I pretty much nailed it.

Mash temps over the hour:

153.1F @ 2:45 p.m.

152.6F @ 3:05

151.5F @ 3:20

150.6F @ 3:45

Fermentation

65 Degrees in primary.

Finishing

Racked from primary onto Surly Furious Dry-hop blend on 10/30/2012.

Racked from secondary w/dry hops to keg on 11/10/2012.

Tasting Notes

While in the Twin Cities for Thanksgiving 2012, I picked up a 4 pack of Surly Furious to compare to my home-brewed version--and to drink.

Copper color. Still a bit cloudy. I didn't use any finings. With 7+ ounces of dry hops some combination of filtering and finings would be necessary to achieve clarity.

The aroma is just about perfect. Enticing citrus notes predominate. Dry hopping did its job.

Thin body. Not quite as thin as the Fixed Gear Clone, but the same problem is evident. I attribute this issue to the precipitous drop in mash temps over the hour-long mash.

Flavor profile matches the commercial version nicely with a couple of exceptions:

1. Mine is not quite sweet enough, this defect goes hand in hand with the thin mouth feel. I have to solve my mash temperature problem if I'm ever going to produce top-notch beers.

2. It also tastes a bit grassy. This sensation is no doubt amplified by the lack of malt sweetness and body. Still, based on the last 2 dry hopped batches I have produced, this and the Fixed Gear, I'm determined never to let dry hops be in contact with the beer for more than 7 days maximum. Even shorter dry-hop periods would probably be better.

Starter:

Boiled 1.8L (final volume) of 1.043 SG starter wort for 15 minutes on Thursday night 10/18/2012. (Wort came from final runnings of Lakefront Fixed Gear Clone. Pitched 1 Activator smack pack of WYeast British Ale II into this starter wort first thing in the morning on Friday Oct. 19.

Mash-in:

Used 3 gallons of boiling water to pre-heat the mash tun. 4.5 gallons 165.5F strike water & 13.38 lbs of cool grain--it's 53F in Kirkwood today and the grain had been outside for a while--combined to reach 153.1F after mash in @ 2:45 p.m. Since my target temp was 153, I pretty much nailed it.

Mash temps over the hour:

153.1F @ 2:45 p.m.

152.6F @ 3:05

151.5F @ 3:20

150.6F @ 3:45

Fermentation

65 Degrees in primary.

Finishing

Racked from primary onto Surly Furious Dry-hop blend on 10/30/2012.

Racked from secondary w/dry hops to keg on 11/10/2012.

Tasting Notes

While in the Twin Cities for Thanksgiving 2012, I picked up a 4 pack of Surly Furious to compare to my home-brewed version--and to drink.

Copper color. Still a bit cloudy. I didn't use any finings. With 7+ ounces of dry hops some combination of filtering and finings would be necessary to achieve clarity.

The aroma is just about perfect. Enticing citrus notes predominate. Dry hopping did its job.

Thin body. Not quite as thin as the Fixed Gear Clone, but the same problem is evident. I attribute this issue to the precipitous drop in mash temps over the hour-long mash.

Flavor profile matches the commercial version nicely with a couple of exceptions:

1. Mine is not quite sweet enough, this defect goes hand in hand with the thin mouth feel. I have to solve my mash temperature problem if I'm ever going to produce top-notch beers.

2. It also tastes a bit grassy. This sensation is no doubt amplified by the lack of malt sweetness and body. Still, based on the last 2 dry hopped batches I have produced, this and the Fixed Gear, I'm determined never to let dry hops be in contact with the beer for more than 7 days maximum. Even shorter dry-hop periods would probably be better.

Thursday, October 11, 2012

Scottish Wee Heavy All Grain Kit from Northern Brewer

Brewed Northern Brewer's All-Grain Wee Heavy Kit a few months ago. Everything went according to plan. Fermented @ 65 or so with WYeast 1728 Scottish Ale yeast. Bottled tonight. 10/11/2012.

Bottling yielded twelve 16 oz. flip top bottles, ten 22+ oz. bomber bottles, and four oddball recycled flip-tops of various sizes. Added .65 oz. of corn dextrose for priming. I guestimated that amount using TastyBrew.com's priming calculator.

Tasting notes:

Bottling yielded twelve 16 oz. flip top bottles, ten 22+ oz. bomber bottles, and four oddball recycled flip-tops of various sizes. Added .65 oz. of corn dextrose for priming. I guestimated that amount using TastyBrew.com's priming calculator.

Tasting notes:

- Mmmmmm!!!!

- You can just begin to taste the alcohol (but not at all in a bad way) which puts the ABV @ 7-8% + (Didn't write down the O.G. on brew day.)

- Clean, malty, Scottish; Just the way a wee heavy should be.

- Mmmmmm!!!!

12/21/2012 Update:

These bottles never carbonated. Barely noticeable carbonation was the goal. Zero carbonation was the result.

Next time:

I think re-yeasting on bottling day may have helped. The beer was crystal clear at bottling, and I don't think there was enough yeast to eat the priming sugar and carb the bottles.

What I would NOT do would be to add more priming sugar for 2 reasons:

1. A fizzy wee heavy is not a wee heavy. It's just weird.

2. If re-yeasting doesn't work, then extra sugar will only make it sweeter, and this bear already has plenty of sweetness in its natural habitat, a Studebaker.

Thursday, October 4, 2012

Viva Nevada Pale Ale or Victorious IPA

Here is the Beer Recipator recipe for the beer I made today, 10/4/2012. It's either a strong/bitter Pale Ale or a weak/mild American IPA. So I gave it two names just to cover all the bases.

Interesting things to note:

Fermentation Temps: 72F (1st 24 hours), 55F (2nd 24 hours), 65F (day 3 thru racking to secondary)

Racked to secondary onto 1 oz. of Citra hops on 10/24/2012.

Interesting things to note:

- Included 8 oz. of Victory Malt in the mash. This was inspired by the fact that I needed some more specialty malt to round out the grain bill and I happened to have exactly 8 oz. of Victory lying around from the Fullerish ESB. Oh and it's apparently not unprecedented to use Victory in an IPA.

- Pre-heated the mash tun by filling it with 3 gallons of boiling water before returning the water to the HLT and re-heating it for the actual mash-in which came later. I attribute the much smaller heat loss (only 1.6 degrees vs. 5 degrees) than I got from the Fixed Gear mash to this step. It took extra time, but with my current system, this will be the best option going forward.

- Forgot to include 1 Tbsp. 5.2 pH mash stabilizer in the mash. Oops. No biggie. This is not a dark beer with lots of chocolate or dark roasted malt, so I'm not worried.

- This was my first attempt at first wort hopping. May have gotten more bitterness out of those initial hops than the Recipator calculated when I entered them as 20 minute hops the way Brew365 suggested.

- My system leaves just less than 1 gallon behind in the boil kettle when it is not tilted during transfer to the primary fermenter. That is just about perfect for the 2.5 oz. of pellet hops in this boil. There was very little good beer left behind with the trub.

- After a few hours (3ish) in my 65 degree ferm fridge, the wort had fallen to 74F. I used my 1/2 gallon at a time aeration method (described fully in the Fixed Gear post), and pitched the wort right onto the Fixed Gear yeast cake. This (6 days in) was a little earlier than I would normally xfer a beer to secondary, but I think it will be fine. I added a whole packet of US05 just to be sure I wasn't under-pitching. I hate under-pitching I probably over-pitched a bit in this case. I'll try to mitigate those effects by xfering to secondary after 1 week and xfering and crash cooling after 2 weeks assuming the fermentation is complete.

- Made sure to use a blow-off tube this time. The combination of my patent-pending aeration method and the ample pitch rate resulted in bubbles in the blow-off system practically instantly. Woot.

- O.G. came in @ 1.049. this is low, definitely in the Pale Ale as opposed to IPA range gravity-wise. Unfortunately, based on the flavor of the hydrometer sample, the bitterness is well into the IPA range. We'll see if/how this potential problem works itself out once fermentation is complete. Good thing I took the Beer Recipator's advice and did not follow my original plan of using .5 oz. Columbus And .5 oz. Chinook as bittering hops.

- Must strategize further how to improve mash efficiency. This time I tried grinding the grain down practically into flour and doing a double batch sparge. I started with 3 gallons of strike water, did a first batch sparge with 3 more gallons, and then did a second batch sparge with another three gallons. This resulted in about 1/3 of a gallon more liquid than I could safely boil in my 7 gallon kettle. It also apparently did not improve my mash efficiency as I had hoped. Note to self for future: the maximum boil volume of your kettle will be reached if you use 8.7 gallons of total mash+sparge water with a 12 pound grain bill. Also, 90 minute boils may be the only way to achieve the desired volume and gravity for the foreseeable future.

Fermentation Temps: 72F (1st 24 hours), 55F (2nd 24 hours), 65F (day 3 thru racking to secondary)

Racked to secondary onto 1 oz. of Citra hops on 10/24/2012.

Transferred to keg for clearing/carbonating on 10/30/2012.

Tasting notes:

Delicious! Enticing aroma--perhaps a bit subtle for an IPA. Good body. Appropriate levels of citrus/grapefruit flavors. That bready victory malt flavor hits just the right part of the palate to balance out all those hops. Maybe just a smidge fewer bittering hops next time. First-wort hopping was a big success. Hop flavor/bitterness is smoother and blends better with the malt background than previous IPA's I've brewed. Citra dry hops are only slightly noticeable on the nose. It's questionable whether their contribution was worth the effort/expense. I would hate for any vegetal or grassy flavors to come through if I left it on dry hops any longer than 7 days, but there's not as much hop aroma as I was expecting. Maybe experiment with pellet hops floating freely rather than leaf hops in a muslin bag. Maybe. It's really hard to complain about this beer--its just so good--esp. for a recipe I just made up out of what I had on hand on brew day. SLIGHTLY less bittering hops would be the only variable I would adjust next time. Definitely a keeper!

Friday, September 28, 2012

Lakefront Brewery Fixed Gear All-Grain Kit from Northern Brewer

Brew date 9/28/2012

Using this recipe.To produce a clone of Lakefront Brewery's Fixed Gear American Red.

Here is the Beer Recipator breakdown of this brew.

Mashed in with 165 on the thermometer. Mash temp after mash-in (at 11:51 a.m. CDT) was 154. Exactly 1 degree F above the target of 153. Since Brew365's Nifty Mash Temp Calculator recommended 164 as the strike temp. It was pretty much dead on. I'm not going to worry about the 1 degree difference.

Here is how the temps for the mash worked out:

11:50 a.m. (pre-mash): 165F

11:51 a.m. (after mash-in): 154F

12:24 p.m.: 152F

12:32 p.m.: 151F

12:41 p.m.: 150F

12:51 p.m.: 149F

Mash

I took the strike water all the way up to boiling before transferring it (with gravity power via nylon hose) to the mash tun.

The initial temp after transfer was 180ish. So I had to wait for it to lose 15 degrees before mashing in. This scenario is by far preferable to transferring at a low temp then trying to heat it back up by drawing off, boiling, and re-introducing 1 gallon of hot liquor at a time which can literally take hours. Trust me.

If I feel daring next time I'll only bring the strike water up to 200F before transferring to save a little time.

The mash rendered 2.75 or so gallons of 1.080 SG wort. The color is a BEAUTIFUL deep red. Since Lakefront recommends a 90 minute boil, I began boiling the first runnings right away. I didn't begin transferring the batch sparge runoff into the boil kettle until over half an hour later anyway.

At the end of the mash I ran the iodine test. I've never done this before and don't think I will again. I had the iodophor sitting around and thought it would feel good to be sure conversion was complete after an hour. Sure enough, it was. The plate on the left is iodophor + first runnings. The plate on the right is iodophor + water as a control.

Sparge

By the time the first runnings were in the boil kettle, the sparge water I had pre-heated had dropped all the way to 150F. I wanted to sparge at a more typical mash-out temperature (170F-ish) so I fired up the burner under the sparge water and waited. When the sparge water (4.75 gallons of it to be exact) had reached 200F+--just this side of boiling--the temperature of the grain (12.5 lbs. plus residual liquid) was around 130F.

Not taking the time to do all the calculations I just brought all 4.75 gallons of sparge water over into the mash tun. When transfer was complete the temperature of the grain-water mixture in the tun was 168--pretty much perfect. I worried a little about small-scale tannin extraction at the spot where the liquid was entering the tun @ 200+ degrees. I would welcome comments about whether this is something worth worrying about or not. If so, the only solution I can think of is a traditional fly-sparging style sparge arm to trickle in the liquid from above. Thoughts? Anyone?

Second runnings SG = 1.030.

Boil

The official 60-minute boil began @ 2:51 p.m. with a .5 oz addition of Columbus hops. The S.G. was 1.052 or so. The first and second runnings had been combined in the kettle and had been boiling for easily over half an hour. I let the last half-gallon of sparge runnings slowly drain from the mash tun during this time. Once this liquid was added to the kettle and the full volume had regained it's boil, I followed the schedule shown below exactly.

BOIL ADDITIONS & TIMES

.5 oz. Columbus (60 min)

.5 oz. Chinook (20 min)

1 oz. Cascade (5 min)

Chill & Transfer

O.G. = 1.060

Aerate & Pitch Yeast

Used my patent-pending (meaning I may or may not apply for a patent at some point in the future) method of aeration.

Begin by allowing wort to settle in a sanitized carboy. Once wort is within 10 degrees Fahrenheit of the yeast that you intend to pitch use a sanitized autosiphon to siphon the wort into a sanitized one gallon container 1/2 gallon at a time. Take each 1/2 gallon of wort and shake vigorously before pouring into a 2nd sanitized carboy. About halfway through this process is a good time to pitch your yeast starter. Terminate the process just before the trub at the bottom of the first carboy starts to sneak into the siphon hose. A few ounces of trub is acceptable.

Ferment

Unfortunately I was only able to make 1.2L of 1.025 SG starter wort. I would have preferred to make 2L of 1.035 starter wort. This being an imperfect world and all, I'll look on the bright side and note that a small amount of weak starter wort is better than no starter wort at all.

On the right side of the photo above is my ferm fridge and Johnson Controls model A419 thermostat. This will allow me to ferment the beer at exactly 65F. At the start of the aeration process the measured temperature of the wort was 74F. As soon as aeration and pitching were complete the carboy of inoculated wort was placed in this ferm fridge and the temp set to 65F. I will check the temp again in the morning.

Dry Hop

1 oz. Citra (dry hop 7 days)

1 oz. Chinook (dry hop 7 days)

Using this recipe.To produce a clone of Lakefront Brewery's Fixed Gear American Red.

Here is the Beer Recipator breakdown of this brew.

Mashed in with 165 on the thermometer. Mash temp after mash-in (at 11:51 a.m. CDT) was 154. Exactly 1 degree F above the target of 153. Since Brew365's Nifty Mash Temp Calculator recommended 164 as the strike temp. It was pretty much dead on. I'm not going to worry about the 1 degree difference.

11:50 a.m. (pre-mash): 165F

11:51 a.m. (after mash-in): 154F

12:24 p.m.: 152F

12:32 p.m.: 151F

12:41 p.m.: 150F

12:51 p.m.: 149F

Mash

I took the strike water all the way up to boiling before transferring it (with gravity power via nylon hose) to the mash tun.

The initial temp after transfer was 180ish. So I had to wait for it to lose 15 degrees before mashing in. This scenario is by far preferable to transferring at a low temp then trying to heat it back up by drawing off, boiling, and re-introducing 1 gallon of hot liquor at a time which can literally take hours. Trust me.

If I feel daring next time I'll only bring the strike water up to 200F before transferring to save a little time.

The mash rendered 2.75 or so gallons of 1.080 SG wort. The color is a BEAUTIFUL deep red. Since Lakefront recommends a 90 minute boil, I began boiling the first runnings right away. I didn't begin transferring the batch sparge runoff into the boil kettle until over half an hour later anyway.

At the end of the mash I ran the iodine test. I've never done this before and don't think I will again. I had the iodophor sitting around and thought it would feel good to be sure conversion was complete after an hour. Sure enough, it was. The plate on the left is iodophor + first runnings. The plate on the right is iodophor + water as a control.

Sparge

By the time the first runnings were in the boil kettle, the sparge water I had pre-heated had dropped all the way to 150F. I wanted to sparge at a more typical mash-out temperature (170F-ish) so I fired up the burner under the sparge water and waited. When the sparge water (4.75 gallons of it to be exact) had reached 200F+--just this side of boiling--the temperature of the grain (12.5 lbs. plus residual liquid) was around 130F.

Not taking the time to do all the calculations I just brought all 4.75 gallons of sparge water over into the mash tun. When transfer was complete the temperature of the grain-water mixture in the tun was 168--pretty much perfect. I worried a little about small-scale tannin extraction at the spot where the liquid was entering the tun @ 200+ degrees. I would welcome comments about whether this is something worth worrying about or not. If so, the only solution I can think of is a traditional fly-sparging style sparge arm to trickle in the liquid from above. Thoughts? Anyone?

Second runnings SG = 1.030.

Boil

The official 60-minute boil began @ 2:51 p.m. with a .5 oz addition of Columbus hops. The S.G. was 1.052 or so. The first and second runnings had been combined in the kettle and had been boiling for easily over half an hour. I let the last half-gallon of sparge runnings slowly drain from the mash tun during this time. Once this liquid was added to the kettle and the full volume had regained it's boil, I followed the schedule shown below exactly.

BOIL ADDITIONS & TIMES

.5 oz. Columbus (60 min)

.5 oz. Chinook (20 min)

1 oz. Cascade (5 min)

Chill & Transfer

O.G. = 1.060

Aerate & Pitch Yeast

Used my patent-pending (meaning I may or may not apply for a patent at some point in the future) method of aeration.

Begin by allowing wort to settle in a sanitized carboy. Once wort is within 10 degrees Fahrenheit of the yeast that you intend to pitch use a sanitized autosiphon to siphon the wort into a sanitized one gallon container 1/2 gallon at a time. Take each 1/2 gallon of wort and shake vigorously before pouring into a 2nd sanitized carboy. About halfway through this process is a good time to pitch your yeast starter. Terminate the process just before the trub at the bottom of the first carboy starts to sneak into the siphon hose. A few ounces of trub is acceptable.

Ferment

Unfortunately I was only able to make 1.2L of 1.025 SG starter wort. I would have preferred to make 2L of 1.035 starter wort. This being an imperfect world and all, I'll look on the bright side and note that a small amount of weak starter wort is better than no starter wort at all.

On the right side of the photo above is my ferm fridge and Johnson Controls model A419 thermostat. This will allow me to ferment the beer at exactly 65F. At the start of the aeration process the measured temperature of the wort was 74F. As soon as aeration and pitching were complete the carboy of inoculated wort was placed in this ferm fridge and the temp set to 65F. I will check the temp again in the morning.

Dry Hop

1 oz. Citra (dry hop 7 days)

1 oz. Chinook (dry hop 7 days)

Subscribe to:

Comments (Atom)