Using this recipe.To produce a clone of Lakefront Brewery's Fixed Gear American Red.

Here is the Beer Recipator breakdown of this brew.

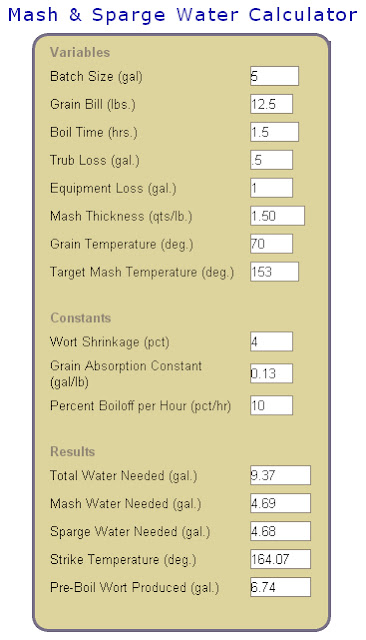

Mashed in with 165 on the thermometer. Mash temp after mash-in (at 11:51 a.m. CDT) was 154. Exactly 1 degree F above the target of 153. Since Brew365's Nifty Mash Temp Calculator recommended 164 as the strike temp. It was pretty much dead on. I'm not going to worry about the 1 degree difference.

11:50 a.m. (pre-mash): 165F

11:51 a.m. (after mash-in): 154F

12:24 p.m.: 152F

12:32 p.m.: 151F

12:41 p.m.: 150F

12:51 p.m.: 149F

Mash

I took the strike water all the way up to boiling before transferring it (with gravity power via nylon hose) to the mash tun.

The initial temp after transfer was 180ish. So I had to wait for it to lose 15 degrees before mashing in. This scenario is by far preferable to transferring at a low temp then trying to heat it back up by drawing off, boiling, and re-introducing 1 gallon of hot liquor at a time which can literally take hours. Trust me.

If I feel daring next time I'll only bring the strike water up to 200F before transferring to save a little time.

The mash rendered 2.75 or so gallons of 1.080 SG wort. The color is a BEAUTIFUL deep red. Since Lakefront recommends a 90 minute boil, I began boiling the first runnings right away. I didn't begin transferring the batch sparge runoff into the boil kettle until over half an hour later anyway.

At the end of the mash I ran the iodine test. I've never done this before and don't think I will again. I had the iodophor sitting around and thought it would feel good to be sure conversion was complete after an hour. Sure enough, it was. The plate on the left is iodophor + first runnings. The plate on the right is iodophor + water as a control.

Sparge

By the time the first runnings were in the boil kettle, the sparge water I had pre-heated had dropped all the way to 150F. I wanted to sparge at a more typical mash-out temperature (170F-ish) so I fired up the burner under the sparge water and waited. When the sparge water (4.75 gallons of it to be exact) had reached 200F+--just this side of boiling--the temperature of the grain (12.5 lbs. plus residual liquid) was around 130F.

Not taking the time to do all the calculations I just brought all 4.75 gallons of sparge water over into the mash tun. When transfer was complete the temperature of the grain-water mixture in the tun was 168--pretty much perfect. I worried a little about small-scale tannin extraction at the spot where the liquid was entering the tun @ 200+ degrees. I would welcome comments about whether this is something worth worrying about or not. If so, the only solution I can think of is a traditional fly-sparging style sparge arm to trickle in the liquid from above. Thoughts? Anyone?

Second runnings SG = 1.030.

Boil

The official 60-minute boil began @ 2:51 p.m. with a .5 oz addition of Columbus hops. The S.G. was 1.052 or so. The first and second runnings had been combined in the kettle and had been boiling for easily over half an hour. I let the last half-gallon of sparge runnings slowly drain from the mash tun during this time. Once this liquid was added to the kettle and the full volume had regained it's boil, I followed the schedule shown below exactly.

BOIL ADDITIONS & TIMES

.5 oz. Columbus (60 min)

.5 oz. Chinook (20 min)

1 oz. Cascade (5 min)

Chill & Transfer

O.G. = 1.060

Aerate & Pitch Yeast

Used my patent-pending (meaning I may or may not apply for a patent at some point in the future) method of aeration.

Begin by allowing wort to settle in a sanitized carboy. Once wort is within 10 degrees Fahrenheit of the yeast that you intend to pitch use a sanitized autosiphon to siphon the wort into a sanitized one gallon container 1/2 gallon at a time. Take each 1/2 gallon of wort and shake vigorously before pouring into a 2nd sanitized carboy. About halfway through this process is a good time to pitch your yeast starter. Terminate the process just before the trub at the bottom of the first carboy starts to sneak into the siphon hose. A few ounces of trub is acceptable.

Ferment

Unfortunately I was only able to make 1.2L of 1.025 SG starter wort. I would have preferred to make 2L of 1.035 starter wort. This being an imperfect world and all, I'll look on the bright side and note that a small amount of weak starter wort is better than no starter wort at all.

On the right side of the photo above is my ferm fridge and Johnson Controls model A419 thermostat. This will allow me to ferment the beer at exactly 65F. At the start of the aeration process the measured temperature of the wort was 74F. As soon as aeration and pitching were complete the carboy of inoculated wort was placed in this ferm fridge and the temp set to 65F. I will check the temp again in the morning.

Dry Hop

1 oz. Citra (dry hop 7 days)

1 oz. Chinook (dry hop 7 days)

Brew Date: 9/28/2012

ReplyDeletePrimary Fermentation Temp: 65F

Transfer to Secondary: 10/4/2012

Secondary Fermentation Temp: 66-70F

Added Dry Hops (without racking): 10/11/2012

Scheduled to Rack to Serving Vessel(s): 10/18/2012

Scheduled to Tap: Poker Night 10/26/2012